The power of innovation

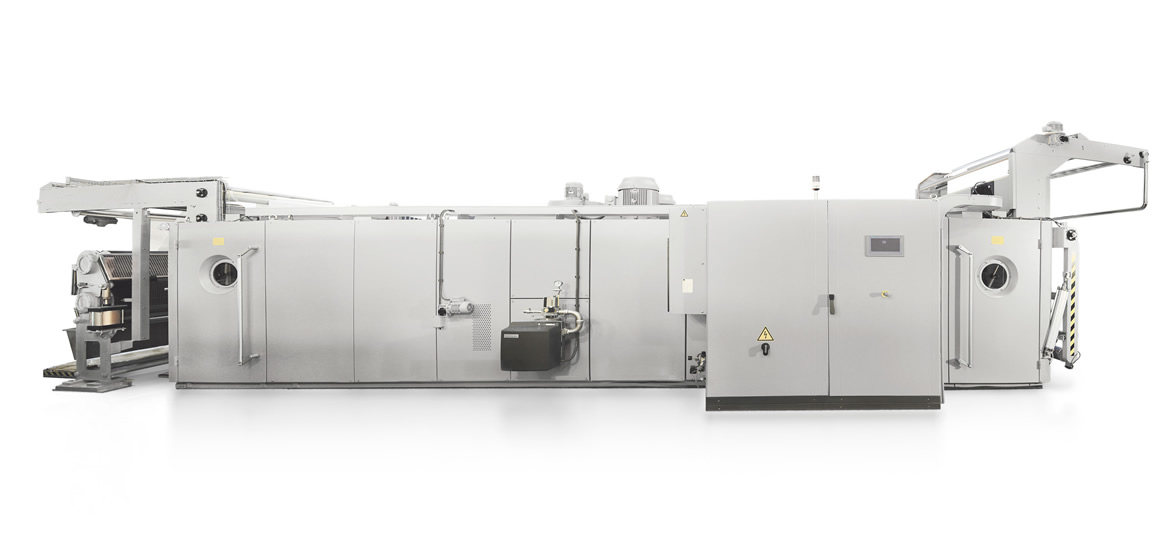

Our latest creation. The L2T machine offers the maximum production capacity with the highest quality standards.

Machine designed and produced solely by us for textile finishing.

Turbang L2T represents a significant advance in the textile finishing industry, the result of decades of experience and research in the field of finishing process systems. Our main objective has been to improve performance and energy efficiency. We have managed to increase performance by up to 35% more than our previous model, TURBANG TSE PLUS L, with no increase in power and energy consumption.

One of the highlights of the Turbang L2T is its ability to be set to relax dryer mode, so it can process extremely delicate fabrics. This ensures that even the most sensitive fabrics can be treated delicately, without compromising the quality and efficiency of the finish.

The Turbang L2T continuous dryer is equipped with multiple grilles that offer a wide range of finishing effects, adapting to different types of fabrics and meeting the most rigorous quality requirements. In addition, thanks to its ability to regulate the angle of impact, or even avoid it if necessary, the Turbang L2T guarantees precise, custom control over the finishing process.

Our priority is to always offer top quality, highly reliable products backed by our renowned guarantee. The Turbang L2T represents the culmination of decades of experience, research and development, and we are excited to offer this advanced technological solution to the textile finishing industry. With the Turbang L2T, you will improve your efficiency, cut production costs and achieve new quality standards in your finishing processes, ensuring a competitive advantage in the market.

Complete insulation of the body

Interchangeable multi-grille system for various finishing effects (patented)

Automatic regulation of air flows for greater efficiency in transport and drying (patented)

Configurable articulated impact angles (patented)

Improved automatic filter, with greater capacity and self-cleaning frequency.

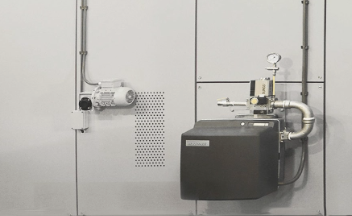

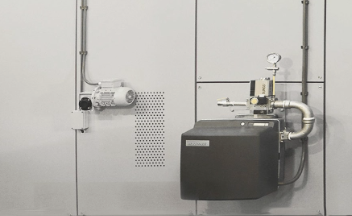

Advanced air recirculation system with moisture control

Remote connection E-WON router

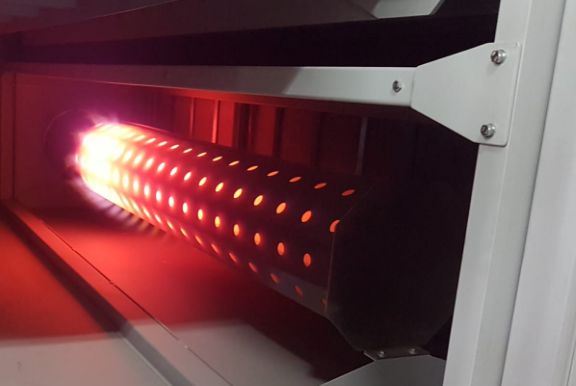

Air-injection Engineering

We have researched and developed innovative air injection systems for the impact and drying of textile webs.

Thermodinamic LAB

We have implemented technological advances based on the laws of thermodynamics for the distribution and use of thermal energy.

Features and accessories

- Pre-installation of programs for easy adjustment on touch screen and TABLET.

- Adaptive power source: gas, electric, thermal oil and steam.

- Antistatic devices and fabric moisture meters. (optional)

- Electronic grammage control.

- 3D thermal insulation.

- Automatic moisture and temperature controls for air extraction.

- Low-maintenance self-cleaning systems.

- E-WON router for remote service over the Internet.

- State-of-the-art air injectors.

- Special battery for air heating.

- Shock device (PATENTED SYSTEM).

- Automatic speed adjustments according to textile web shrinkage.

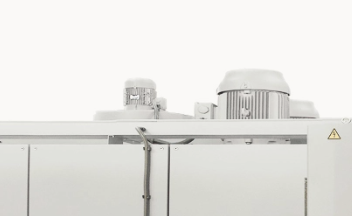

- High-performance fans activated by inverters.

- Advanced air recirculation system.

- Mahlo automatic weft straightener.

- Expandable modular design at floor or upper level.

- Particulate filter and compactor option (optional).

- Foulard padding mangle with double or triple roller wringing system (PATENTED SYSTEM).

- High capacity to accumulate fabric inside.

- Very high evaporation capacity with minimal energy consumption.

- Interchangeable multi-grille system for various finishing effects (PATENTED SYSTEM).

- Adjustment of impact angles (PATENTED SYSTEM).

The finish you want for your fabrics starts here.

Contact us and we will advise you.